Exploring the Role of Pneumatic Actuators in Malaysia’s Industrial Growth

What Are Pneumatic Actuators?

A pneumatic actuator is a device that uses compressed air to create mechanical movement. This movement can be either straight (linear) or rotating, depending on the type of actuator. Pneumatic actuators are commonly used in industries like manufacturing, packaging, and food processing, where accurate motion and dependable performance are crucial.

Benefits of Pneumatic Actuators in Malaysia

Cost-Effective

Pneumatic actuators are affordable compared to electric or hydraulic alternatives, helping businesses improve efficiency without large capital investment.

Energy Efficient

Using readily available compressed air, pneumatic actuators are energy-efficient, reducing operational costs while maintaining performance.

Speed and Precision

Pneumatic actuators offer fast response times and precise control, boosting productivity and accuracy in industries like automotive and electronics.

Reliable and Durable

Known for their durability, pneumatic actuators perform well in demanding environments, making them ideal for industries like food processing and textiles in Malaysia.

Types of Pneumatic Actuators

Different types of pneumatic actuators are available to suit specific applications. The most common types include:

Linear Pneumatic Actuators

These actuators generate straight-line motion and are widely used in material handling, assembly lines, and packaging.

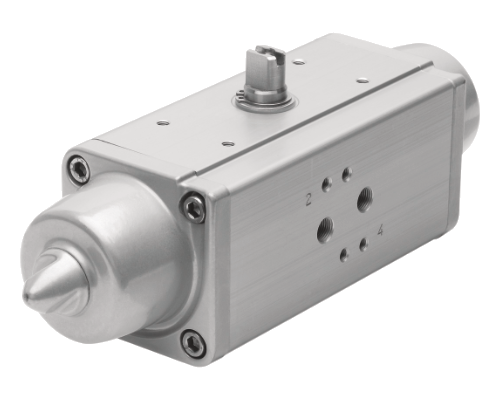

Rotary Pneumatic Actuators

Used for applications that require rotary motion, such as valve control and robotic arms.

Compact Pneumatic Actuators

Smaller versions of linear actuators, ideal for installations with limited space.

Vane Pneumatic Actuators

Often used for valve control and applications requiring high torque in a compact design.

Key Applications in Malaysian Industries

In Malaysia, pneumatic actuators are used across various industries:

Manufacturing

Pneumatic actuators are crucial in automation systems for assembly lines, robotic arms, and machine operation, helping businesses improve production efficiency.

Packaging

Pneumatic actuators control the movement of conveyors, lifting mechanisms, and sealing machines, ensuring smooth and rapid packaging processes.

Food Processing

Due to their hygienic design and reliability, pneumatic actuators are used in food handling, conveyor systems, and packaging, ensuring consistent performance in food production environments.

Textiles and Printing

Pneumatic actuators control machinery used in fabric handling, cutting, and printing processes, enhancing precision and reducing downtime.

Choosing the Right Pneumatic Actuator Supplier in Malaysia

Selecting a reliable supplier is essential for obtaining high-quality pneumatic actuators. Leading brands such as Airtac Malaysia, Festo Malaysia, and SMC Cylinder Malaysia offer durable and efficient pneumatic actuators tailored to various industrial needs. These suppliers provide excellent customer support and can help businesses select the most suitable actuator for their applications.

Conclusion

Pneumatic actuators are essential for industries in Malaysia looking to improve automation systems. They offer cost-effectiveness, energy efficiency, and reliability, driving better productivity and lower costs. Choosing the right pneumatic actuator and supplier is crucial for long-term success. Explore quality pneumatic actuators today to enhance your industrial processes in Malaysia.