Festo Regulator Malaysia: Precision in Pneumatic Pressure Control

November 4, 2025Pneumatic Actuator Malaysia: Advanced Guide to Selection, Performance & Applications

Introduction

Pneumatic actuators are essential components in modern industrial automation, they convert compressed air into mechanical motion (linear or rotary), enabling machines to move, clamp, open/close valves, or perform other tasks with precision and speed. While Malaysia has increasingly adopted automation, many plant managers and design engineers still face challenges in selecting the right actuator for their specific needs: matching torque, environment, speed, mounting standards, etc.

This guide covers what you need to know: types of pneumatic actuators, critical performance specifications, selection best practices, supplier criteria, industry-specific use cases, and how Pneumotion offers suitable actuator solutions via their product range: Pneumotion Festo Actuators.

Types of Pneumatic Actuators & Use-Case Scenarios

Here are several actuator types, their mechanisms, and where they are commonly used in Malaysia:

Actuator Type | Mechanism & Characteristics | Typical Applications in Malaysia |

Linear actuators / pneumatic cylinders | Move a piston in a straight line. Available single-acting (spring return) or double-acting. High speed, simple design. | Conveyors, packaging lines, clamp & press devices, pick-and-place operations. |

Rotary actuators (rack & pinion / vane / scotch-yoke) | Convert air pressure into rotary motion (usually 90°, stepped or modulating). Rack & pinion offers high torque in compact bodies. | Valve automation (butterfly, ball, plug), dampers, shut-off valves. |

Compact / Mini actuators | Smaller footprint, lighter weight. Reduced bore or stroke for tight spaces. | Electronics, assembly automation, lab equipment, robotic grippers. |

Spring-return / Fail-safe actuators | Include internal springs or return mechanisms so the actuator defaults safely on power or air loss. | Safety doors, emergency valves, fail-safe systems in chemical plants. |

Heavy-duty or Corrosion-resistant actuators | Built with stainless steel, protective coatings or housing to handle heat, moisture, corrosive agents. | Wastewater treatment, marine facilities, acid plants, palm oil mills. |

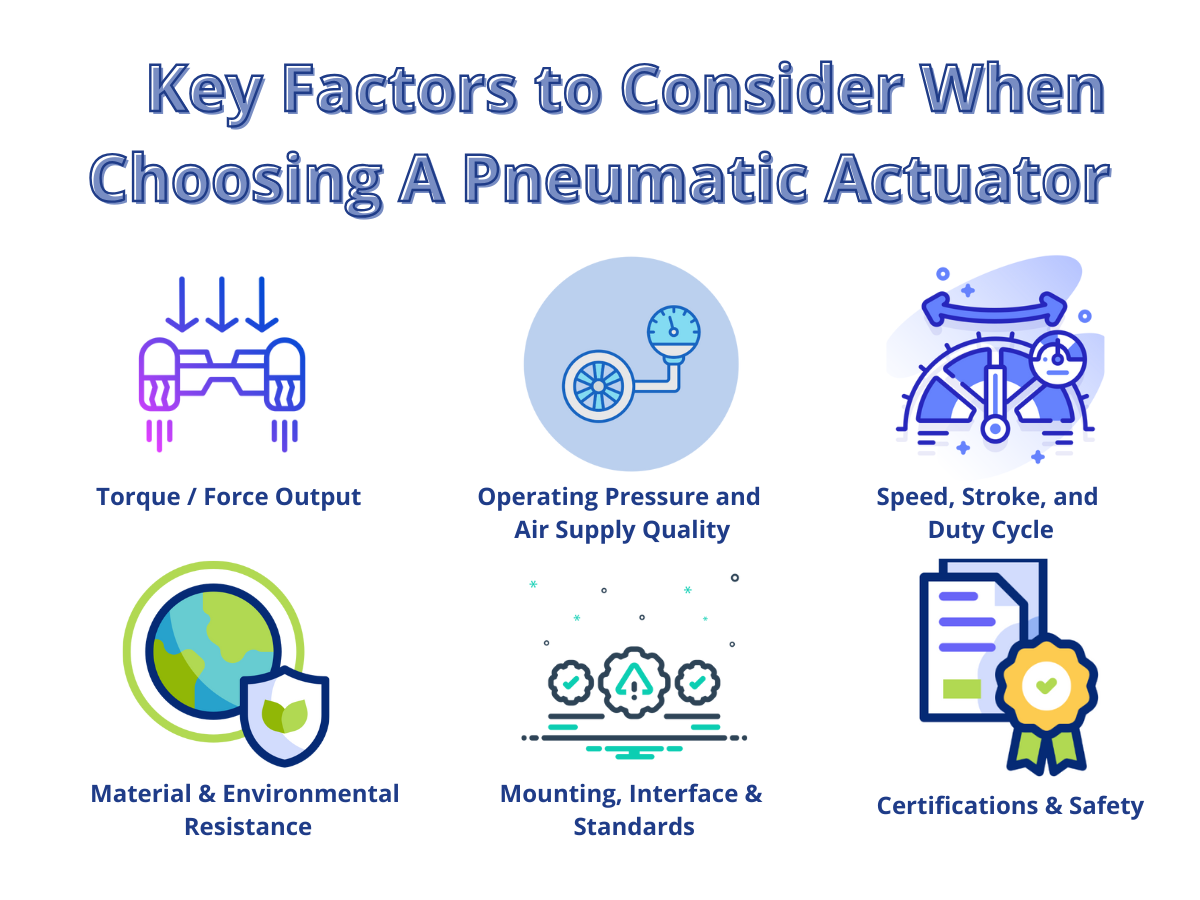

Critical Specifications & Performance Factors

To choose the right actuator, it’s not enough to just know type, you must ensure its specifications align with your needs. Below are important factors:

Torque / Force Output

- For rotary actuators, ensure torque output exceeds the required torque for your valve or load by a safety margin (typically 25-40%).

- For linear actuators, check force = pressure × piston area; ensure required force includes friction, inertia, and load.

Operating Pressure and Air Supply Quality

- Malaysia typically uses compressed air in the range ~ 4-8 bar for many industrial setups, but higher or lower ranges may apply.

- Air must be clean, dry, oil-free where food, pharmaceutical, or electronics are involved. Use FRL units (Filter, Regulator, Lubricator) if needed.

Speed, Stroke, and Duty Cycle

- Stroke length: Long strokes may require rodless or guided actuators.

- Cycle speed: Rapid cycling requires actuators with fast response, minimal hysteresis, good sealing, and cooling or buffering.

- Duty cycle: How many cycles per minute/hour. Continuous or heavy usage requires robust construction and quality seals.

Material & Environmental Resistance

- For a humid tropical climate, choose stainless steel or anodised aluminium bodies.

- Corrosive/chemical exposure (acid, salt, cleaning agents) demand special materials or protective coatings.

- Temperature extremes: high (>60-80°C) or low temperatures may require special seals or designs.

Mounting, Interface & Standards

- ISO standards (e.g. ISO 5211 for valve mounting) ensure compatibility.

- NAMUR pattern for accessory mounting (limit switches, solenoids).

- Mounting style (flange, bracket, foot, trunnion) should match your machine layout.

Certifications & Safety

- Certifications like CE, ATEX (for explosive environments), IP ratings for dust/water ingress.

- Safety features: spring return or fail-safe mechanism, cushion stops, stroke limit adjustments.

Selecting a Resistant & Reliable Supplier in Malaysia

Choosing the actuator supplier is as crucial as choosing the actuator. Suppose a subpar supplier provides low tolerance, poor sealing, or late delivery, that can lead to increased downtime and higher TCO (Total Cost of Ownership). Here are the criteria:

- Brand Portfolio & Genuineness: Looks for authentic, branded actuators (e.g. Festo), not knock-offs. Pneumotion’s catalogue of Festo actuators reflects such reliability.

- Stock & Lead Time: Local stock minimises downtime. Suppliers with reliable delivery pipelines.

- Technical Support & Customisation: Many applications need custom stroke, special bolts, or mountings; good suppliers offer support.

- After-sales Service: Spare parts, seal kits, servicing, and maintenance advice.

- User Feedback & Case Studies: Real examples in similar industries (palm oil, food processing, automotive) show supplier capability.

- Warranty & Return Policies: Clear warranty terms, easy replacement of faulty units.

Examples & Industry Trends in Malaysia

- Higher Adoption in Process Automation: Industries such as palm oil milling, petrochemical, water treatment are increasing demand for robust rotary actuators capable of handling harsh environments.

- Focus on Fail-Safe & Safety Features: Safety standards and regulatory pressure mean more systems now require spring-return or double acting actuators with fail-safe springs for emergency shut-off.

- Environmental & Energy Efficiency Concerns: Pneumatic systems are under scrutiny for air leakage losses and energy inefficiencies; choosing well-sealed, high-efficiency actuators is becoming standard practice.

- Digital / Smart Control Integration: Position feedback (limit switches), integration with PLCs, embedded sensors are being requested more often.

Why Pneumotion Builds Value in Your Pneumatic Actuator Choices

Pneumotion offers a competitive edge:

- Their Festo actuator range includes rotary, linear, and other actuator types suited for many industries.

- Technical expertise: helping you match actuator torque, stroke, mounting, environment.

- Quality assurance with branded parts ensures durability.

- Responsive local after-sales service and spare parts support.

FAQs: Pneumatic Actuators in Malaysia

Conclusion

Pneumatic actuators are a backbone in many Malaysian industries, driving valves, dampers, machines, and conveying systems. Choosing the right actuator involves understanding torque, environment, duty, mounting standards, and supplier credibility.

For businesses that demand reliability, precision, and long-term value, Pneumotion’s Festo actuator line provides multiple actuator types, backed by local support and product authenticity.

Explore Pneumotion’s Festo Actuators to find the right actuator for your needs. For technical assistance or bespoke actuator selection, please contact us.